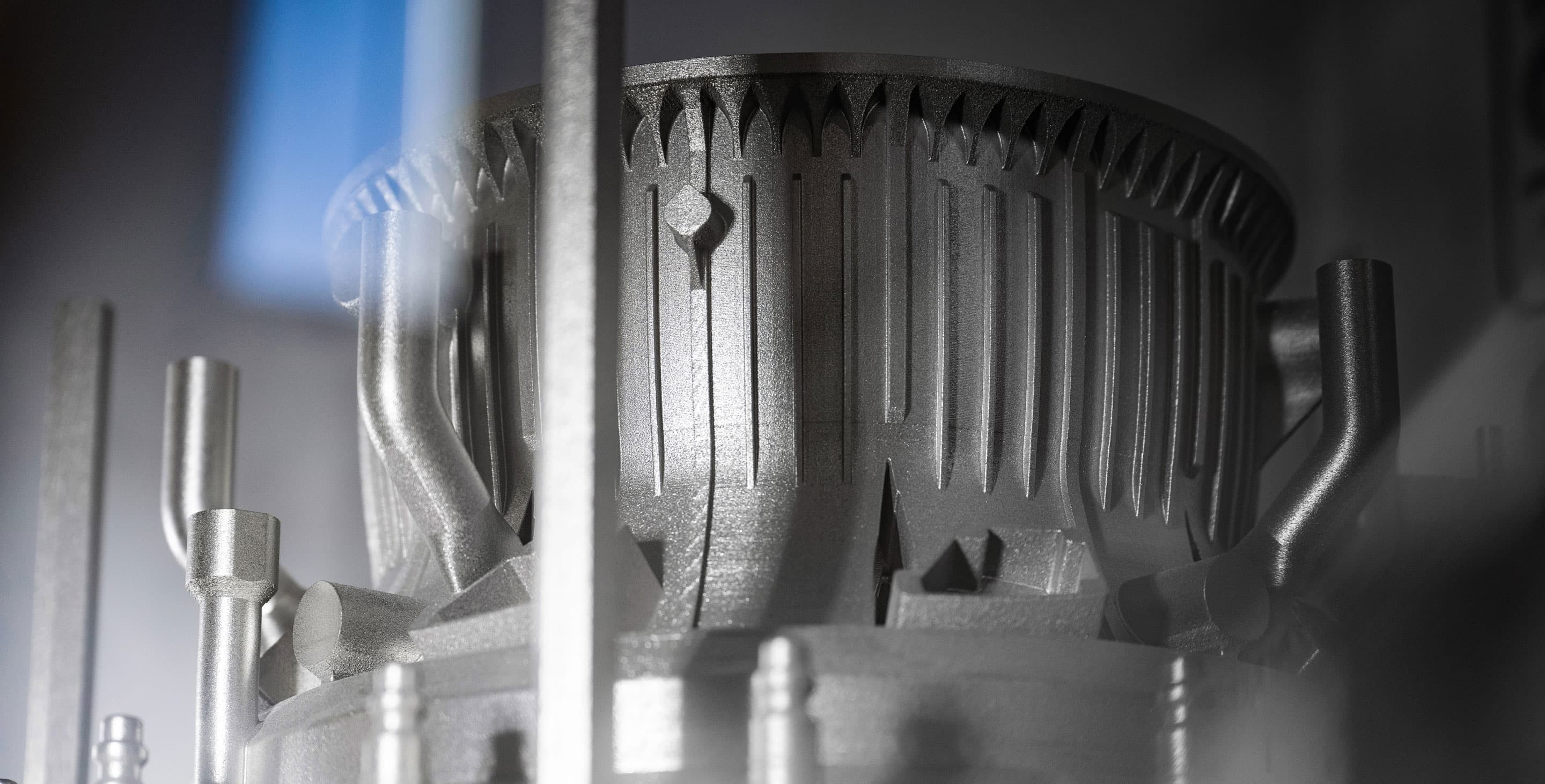

Metal Additive Manufacturing

For The Biggest Design Challenges

Don't let traditional manufacturing limitations get in the way of your design vision. Imagine it and we can make it straight from a 3D model so you can realize the untapped potential of additive and unfettered design freedom.

Your Mission is Ours

Beehive Industries is one of the largest contract manufacturers for metal printing in the U.S. We take each project personally, which is why we work directly with you from the earliest stages of design to production.

We Do It All

Our team of manufacturing specialists are with you every step of the way with Beehive Industries® specialists.

Design Optimization

Additive Manufacturing

Machining

Welding

Post-Processing

Inspection

Quality Assurance

High-Volume Production

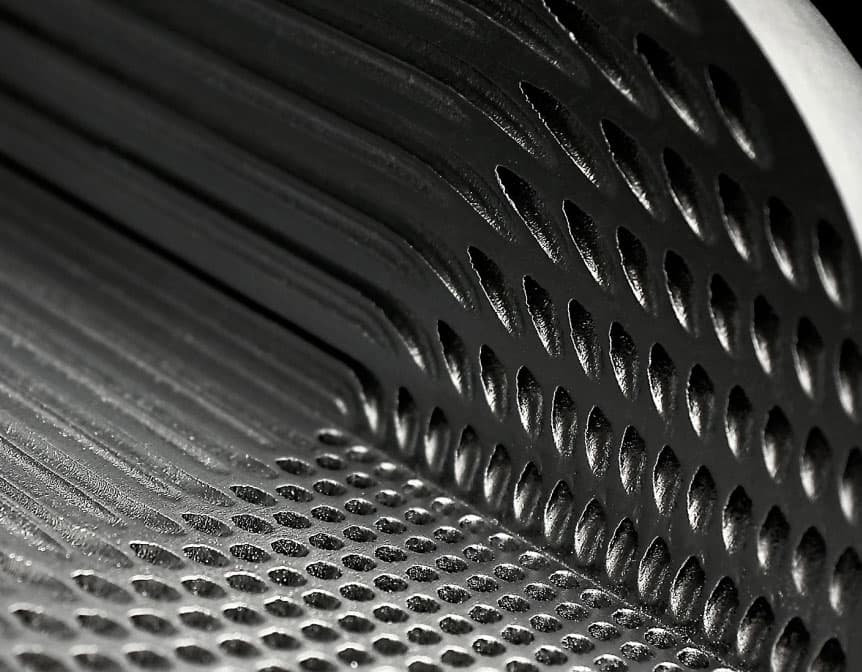

We maintain one of the largest fleets of small, large, single, and multilaser machines.

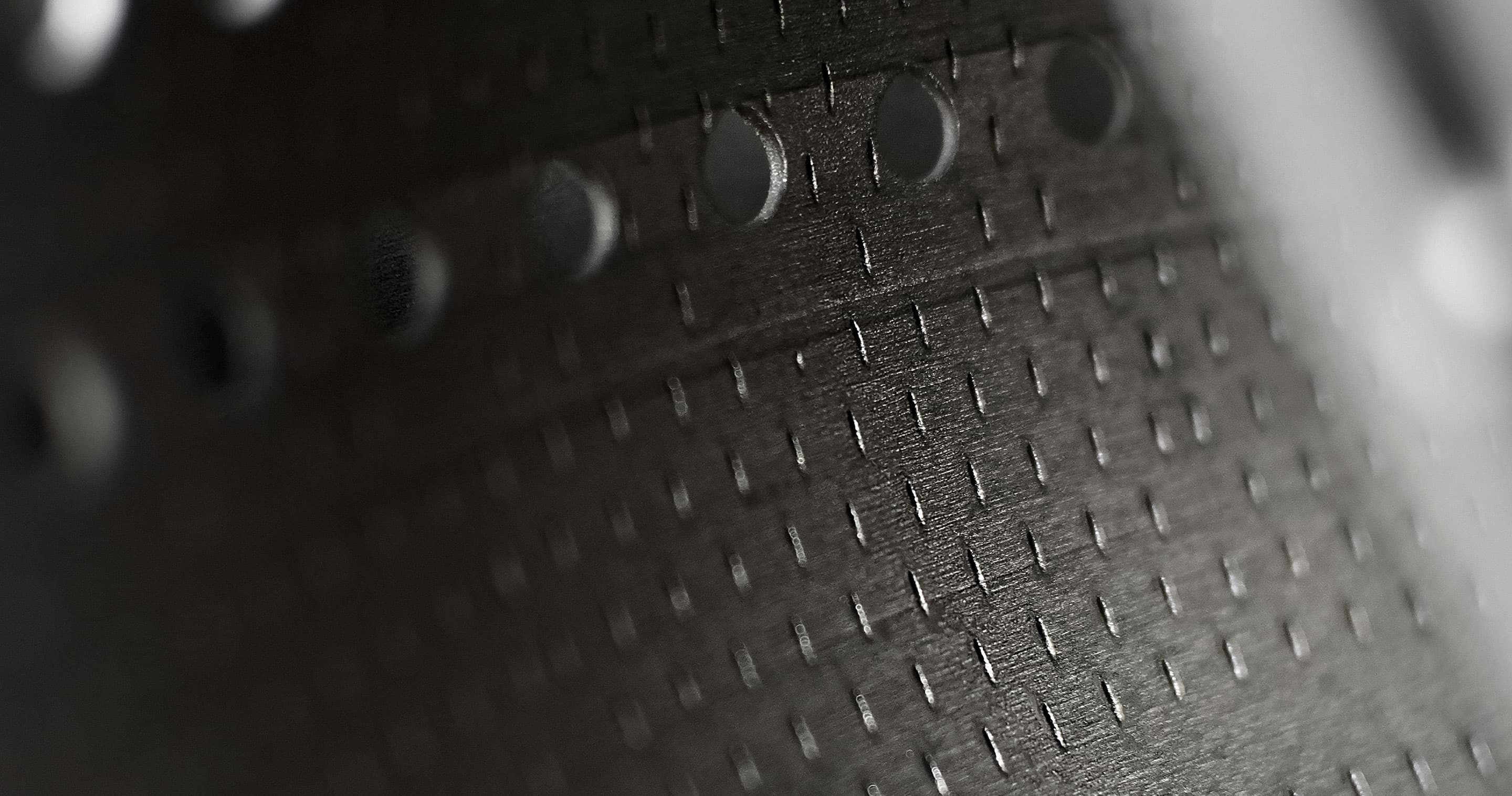

Surface Quality

Print with industry-leading surface quality, known for its high accuracy and smooth finish.

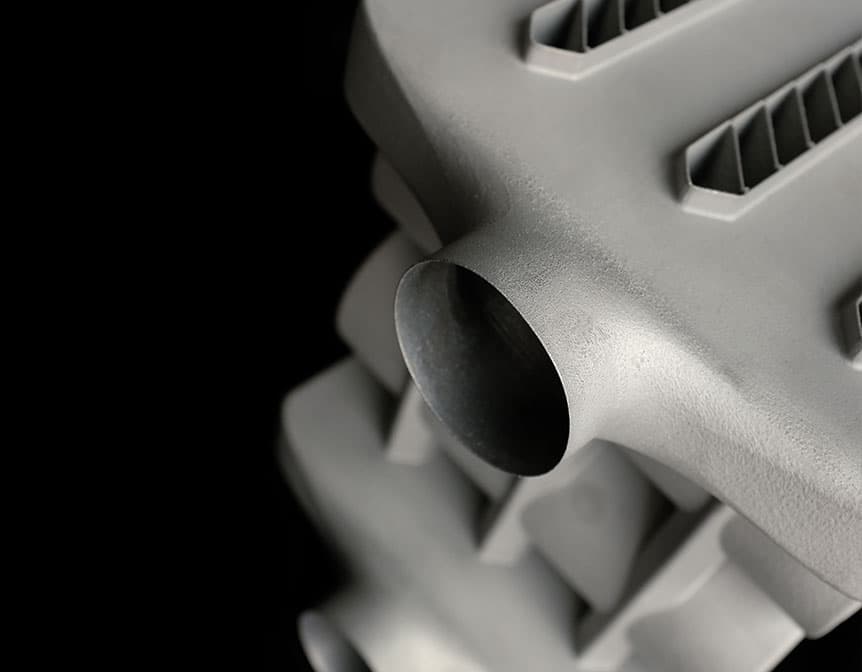

Doesn't Exist?

Let's Make It

Leverage one of the most comprehensive collections of certified, aerospace-grade powders or we’ll work to make even superalloys printable for your program.

Aluminum

Nickel

Cobalt

Titanium

Refractory

Why Print Metal?

Rapid prototyping

Design customizations

Reduced weight

Advanced performance

Part consolidation

Minimized assembly time

Improved flexibility

Less material waste

Quality assurance

Accelerated cycle time

Low supplier dependence

No obsolete parts

Local production and access